XPS, the thermal insulation material made of extruded polystyrene, is produced with extrusion by melting and forming special polystyrene foam into various shapes. Extruding machines release a continuous flow of hard thermal insulation foam with thicknesses from 20 to 200 mm. The continuous foam flow is then cut to the desired lengths and its edges and surface are shaped according to specific uses. This is why we should observe which edges and surface treatments are most appropriate for our individual use. Read more about it below.

PICTURE 1: smooth panel leaving the extrudor in production line

PICTURE 1: smooth panel leaving the extrudor in production line

Choice of different XPS panels

SMOOTH PANELS

Smooth XPS panels are not additionally processed.They are merely cut to shape without any surface treatment. Smooth panes are especially appropriate for demanding applications, such as below grade installation. They are suitable for longterm exposure to water intake by absorption and diffusion, as their cell structure is closed and they are practically non absorbent.

Smooth XPS panels are used in:

- below grade applications,

- in moist surroundings,

- below underground water levels,

- in inverted roof systems,

- as waterproofing protection.

All producers declaring their thermal insulation suitable for use in demanding applications must prove the necessary characteristics with an European Technical Assessment (ETA). An ETA is achieved after extensive testing and sampling in order to prove that the product is safe to use and of desired quality. Even though these processes are tedious and long, we must keep in mind that this the only way to ensure the durability and construction quality of our building and its thermal envelope. You can read more about below grade thermal insulations here.

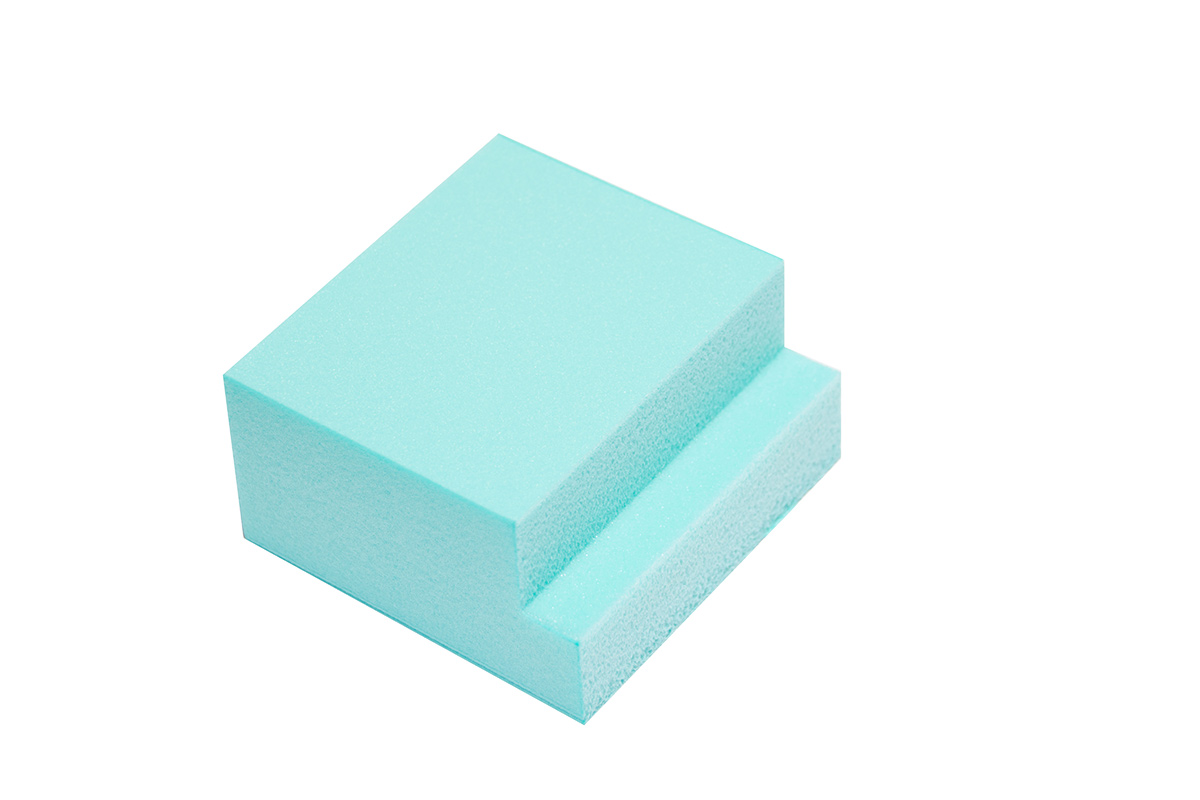

PICTURE 2: A smooth panel with ship-lap edges

PICTURE 2: A smooth panel with ship-lap edges

PANELS WITH ROUGH SURFACES

Waffle surface panels

After foaming, panels with waffled surfaces are treated with especially designed machines. Thus, a thin layer of surface cells is open and embossed with a waffle structure. This treatment makes for an ideal surface for further rendering or subsequent panel application with final layers.

Mostly, further surface applications of waffle panels are:

- with glues and adhesives,

- with mortars,

- with ceramic tiles

- with final renders even on moist interior walls.

Often, waffle panels are used in the prevention of thermal bridges in lintels and vertical concrete binds where a final rendering is to be expected and we should aim for good adhesion properties.

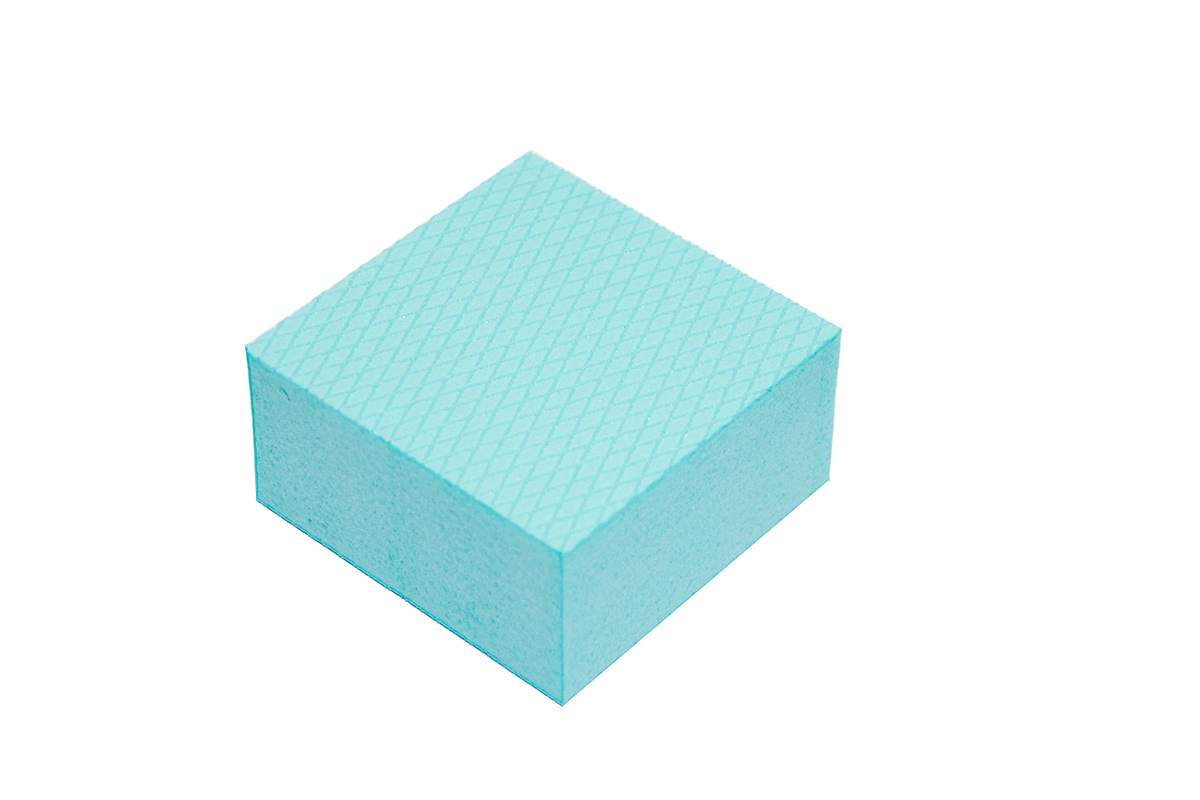

PICTURE 3: waffle structured panel with cut edges

PICTURE 3: waffle structured panel with cut edges

Even though a small part of surface cells is open, a vast majority is still closed and filled with air. These panels are used for applications in facades and plinths.

Panels with grooved surfaces

Rough surface panels are additionally treated with grooves. Due to their improved tensile strength, grooved XPS panels are mostly used in applications where heavier final layers will need additional adhesion, such as in stone cladded plinths. You can read more about energy efficient stone cladded facades in our Quick Guide.

PICTURE 4: XPS panel with grooves

PICTURE 4: XPS panel with grooves

WHAT ABOUT THE EDGES?

The type of edges should be chosen according to application. We can choose between ship-lap edges, straight edges and tongue and groove edges.

Ship-lap edges

Ideally, ship-lapp edges panels are best used for reduction of linear thermal bridges at panel junctions when panels are only layed in one layer. Thus, convective heat transfer through gaps between panels is prevented.

Straight edges

Straight edged panels are used in multilayered applications.

Tongue and groove edges

Panels with tongue and groove edges are also very good in the prevention of linear thermal bridges. Due to easy installation, they areis ideal for roofs and ceiling applications.

+386 7 39 39 510

+386 7 39 39 510 advice@energyshield.biz

advice@energyshield.biz