According to the newest trends in energy efficient construction and environment preservation, buildings must be designed with a considerably thicker thermal insulation layer. Simultaneously, any uncontrolled heat losses must be prevented by designing highly airtight building envelopes. Failing to properly address both of them may result in one of the biggest mistakes in the design of a building, creating a stronge thermal bridge.

Why is this such a big mistake?

In airtight and thermally well-insulated buildings, thermal bridges cause significant energy losses because of intensive thermal flux. While U-values (thermal conductance) in walls, roofs and floors of energy efficient buildings are extremely low (U=0,15 W/m2K), U-values in badly designed junctions may reach a 13 times higher heat transmittance at U≈2 W/m2K, creating a significant thermal bridge. In a few years, mold will occur on the thermal bridge area as well as signs of materials decay – both obvious health hazards.

Problematic crossing

The most pressing problem is the crossing area where exterior walls join the floor in contact with ground. Why? Because in this area, architects usually decide to interrupt the flow of exterior thermal insulation and continued on the interior below the screed. In doing so, they are interrupting the building’s thermal envelope. Obviously, it does not help if the floor is in contact with ground.

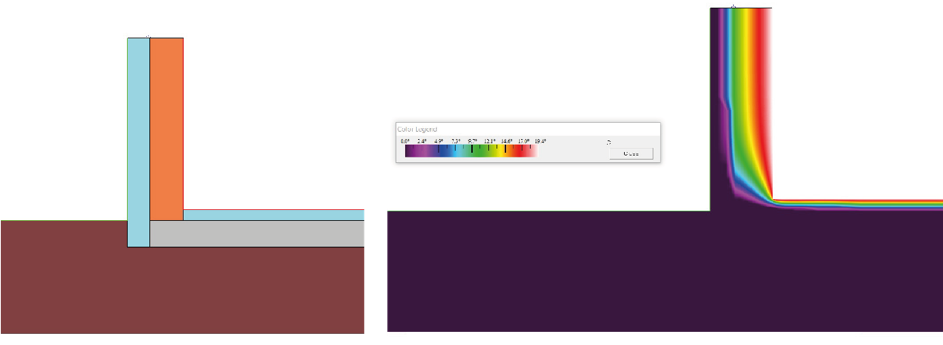

As shown with in Therm simulations in the picture below, significant heat flow causes very low interior surface temperatures on wall, almost dropping to zero in the corner area – ideal conditions for the formation of condensate from moist air.

This bad design is usually caused by trying to cut corners without thinking too much about the consequences. Judging by the near low indoor corner temperatures, it is definitely a bad idea!

Solution

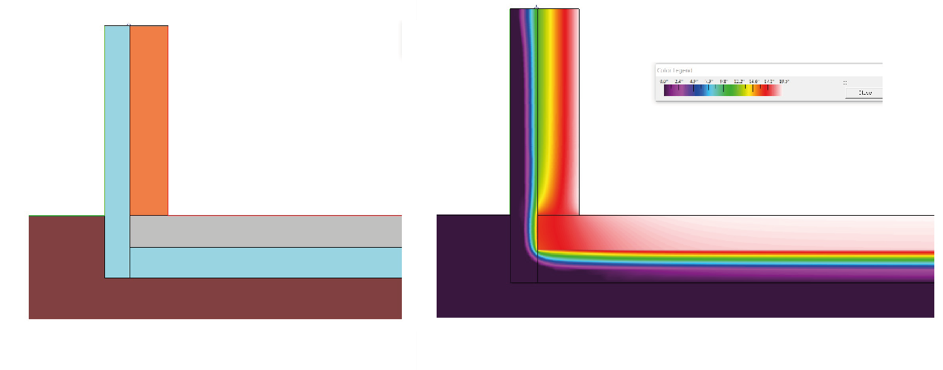

The only solution to prevent this is to continue the thermal insulation uninterruption along the exterior walls and below grade, also below the foundation slab. At first, installing thermal insulation below the foundation slab seems a strange idea, but handled correctly, it is quite simple. We must, however, chose the right design and use appropriate material with abundant compresive strength, no water absorption with ETA – the European Technical Assessment documentation. Special attention should be given to the protection of the waterproofing layer below the foundation slab. Below grade, waterproofing is laid between two layers of thermal insulation made of extruded polystyrene. We call this solution the SEISMIC foundation pillow.

Now let us repeat the above Therm simulation and check our surface temperatures when thermal insulation is applied from the exterior without interruption. Obviously, the situation is very different and surface temperatures reach 20 degrees Celsius. There is no chance for the formation of condensation.

Evidently, we at Fibran need not worry about “our” homeowners, as even later on, they will not encounter problems with mold or material decay. On the contrary, by doing it right, they will enjoy a healthy living environment in a durable home.

+386 7 39 39 510

+386 7 39 39 510 advice@energyshield.biz

advice@energyshield.biz